Runners who assiduously perform the strength-training regimen outlined in chapters 5 through 9 of this book, arrange their training to conform to the basic tenets of an intelligent training program as explained in chapter 2, and take the time to perform the injury-prevention exercises described in chapter 10 can still be stymied in their efforts to improve running performance. Simply by wearing the wrong training shoes or the wrong orthotic device for his or her foot type, a runner may short-circuit his or her well-intentioned efforts to improve. This chapter endeavors to present some sound wisdom about footwear and orthotic selection by presenting an overview of how and why running shoes are constructed for particular biomechanics and how runners can choose the right footwear and orthotics for their specific needs.

Why Wear Running Shoes?

Running shoes work for running because they are designed and manufactured to meet the demands of bearing three to four times the body’s weight on impact, are designed for the biomechanics of running that are outlined in chapter 3, and are biomechanically (and, to a lesser extent, terrain) specific.

Running shoes are designed on lasts, or forms that are models of the human foot. These lasts have shapes ranging from curved to straight with variations on the degrees of the curve, which make the shoes appropriate for the various foot shapes of runners. The term last also applies to the methodology of construction. A combination-lasted shoe stitches the upper fabric underneath a cardboard heel to provide stability. A slip-lasted shoe stitches the upper directly to the midsole, ensuring flexibility. A full-board-last (cardboard from heel to toe) shoe is the most stable lasting technique but currently is almost nonexistent in shoe manufacturing.

Theoretically, curved slip-lasted shoes are designed for higher-arched, rigid feet, whereas straight combination-lasted shoes are designed for flatter, more flexible feet. Because flat feet tend to pronate (the inward rolling of the rear foot, controlled by the subtalar joint) more than high-arched feet, straight-lasted shoes, with the aid of stability devices embedded in the midsole, help limit the rate and amount of pronation. Conversely, runners who underpronate should wear curved to slightly curved slip-lasted shoes, which allow the foot to generate as much pronation as possible to help aid in shock absorption.

Many runners err in choosing shoes because they do not know what foot type they have. If an underpronator trains in stability shoes, predictable injuries like calf pain, Achilles tendinitis, and iliotibial band syndrome will occur. If an overpronator trains in a cushioning-only shoe, stress injuries (including fractures) to the foot, tibia, and the medial knee likely will occur. For most runners, a qualified employee at a running specialty store can evaluate foot biomechanics, possibly by using a treadmill and a video camera, and successfully recommend multiple shoe models that, in theory, will prevent injury and provide a pleasurable ride. Occasionally, evaluating the foot becomes tricky due to motion not seen clearly by the naked eye, and a slow-motion camera may be needed to ascertain true foot movement. This is rare and usually not found in recreational runners due to lower training volume and velocity. Understand that biomechanics can change; what was once corrected may no longer be a problem, and new problems can arise.

History of 20th-Century Running Shoes

The history of the running shoe in the 20th century begins with Spalding’s introduction of the long-distance running shoe. The company outfitted the 1908 U.S. Olympic marathon team in its models, and based on observations of the marathon and the shoes’ performances, it created a line of marathon shoes in 1909. Both high-top and low-top shoes with a pure gum sole and leather uppers were “full finished inside so as not to hurt the feet in a long race.” Within five years, the gum rubber sole had been replaced by the leather sole, and the research and marketing of running shoes had begun in earnest, albeit in fits and starts.

Although Spalding continued tinkering with its running shoe models, the intrigue in running shoes sparked by the 1908 Olympic marathon in London gave way to a fascination with track spikes, particularly those manufactured by the Dassler brothers of Germany. Worn by Jesse Owens in the Munich Olympics, the spiked shoes were little more than a soft leather upper sewn to hard leather soles with permanent “nails” built into the soles to provide traction on the dirt tracks.

An interest in production of running shoes was rekindled in the United States in the mid-1960s through the mid-1970s, which ushered in the era of the running specialty business. Facing competition from the Japanese-imported Tiger running shoes, Hyde, New Balance, and Nike all began production of serious running shoes. The features of the new shoes were a higher heel, midsole cushioning material (EVA), and nylon uppers.

In some cases, the shoes were well made; in most cases, they were not. By the late 1970s, Runner’s World began lab-testing the running shoes, and the manufacturers were forced to improve the quality of their shoes or lose market share. This change in the mind-set of the companies began a period of intense competition (that still lasts today) to provide the best fit with the most cushioning, stability, and durability in a shoe that looks good.

Components of Running Shoes

This section describes the components of the running shoe and their significance for the runner. The emphasis is on finding the right shoe, from a biomechanical and a fit standpoint. One part of the equation without the other could lead to injury. When purchasing shoes, remember that the cost of the shoe does not ensure its success. For one runner, an expensive shoe may only deplete his bank account without aiding performance; for another, the shoe may be expensive and perfect. Your foot type, shape, and biomechanics determine what is best when it comes to shoes.

Upper

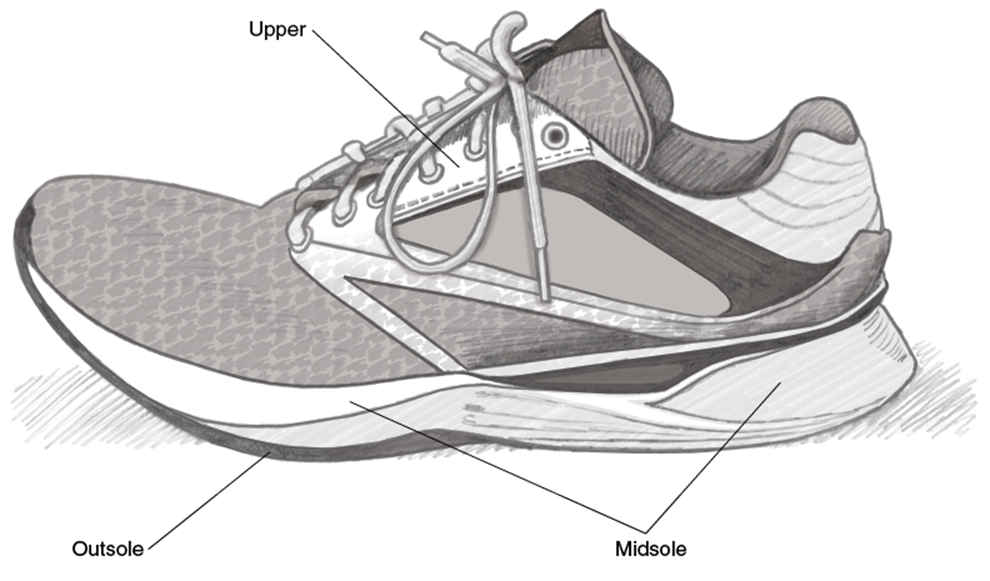

The upper of a running shoe (figure 11.1) is the material that covers the top and the sides of the foot. It can be made of multiple pieces of fabric sewn or glue-welded together, or it can be made of a one-piece, seamless material. All current running shoes are of human-made materials (nylons) for breathability, comfort, and weight reduction. Leather is no longer used because of its lack of breathability, nonconforming shape after repeated use, weight, and cost.

Figure 11.1 Lateral view of shoe: upper, midsole, and outsole.

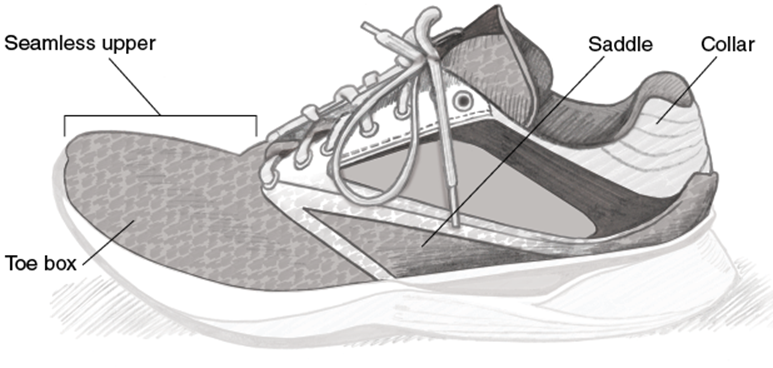

The front of the upper is referred to as the toe box of the shoe (figure 11.2). It takes its shape from the last of the shoe (the form the shoe is built on), but its style is determined by the shoe designer to meet the needs of the shoe wearer. The toe boxes of many of the shoes built recently are wider and deeper to accommodate the higher-volume feet that seem to have become more prevalent as the second running boom has corralled more recreational runners with larger frames into the sport. The midfoot of the shoe’s upper can be designed in conjunction with or independently of the lacing system (e.g., ghillie lacing) to allow for various upper fits. Occasionally, companies will attempt a nonsymmetrical lacing pattern ostensibly designed to improve the fit of the upper and remove “hot spots” (pre-blister-forming areas) from developing on the foot during running.

Figure 11.2 Upper.

The design of the upper of the shoe determines the fit of the shoe—not the length of the shoe, but how the shoe envelops the foot. This is important because if the shoe fit is improper, the biomechanical needs of the runner may not be met. Only when the fit of the shoe is spot-on can the function (be it stability, motion control, or cushioning) work as designed. For example, if the fit of the upper is too baggy in the midfoot, excessive pronation can occur despite the presence of a medial support. The lack of a proper fit renders the stability device ineffective in combating the pronation it was designed to limit. Injuries can occur—in this case, tibial pain—even if a runner wears a shoe that is the correct category for his or her foot type.

This scenario often leads to disenchantment when purchasing shoes because of the confusion resulting from following the suggestions and guidelines and still not getting relief from pain. Here is a general point when purchasing shoes: If the shoe doesn’t fit your foot well, it isn’t the best shoe for you, regardless of whether its biomechanics are matched to your foot type. For example, it could be argued that for a mild overpronator, a cushioned shoe that fits perfectly is more stable than a mild stability shoe that is too roomy.

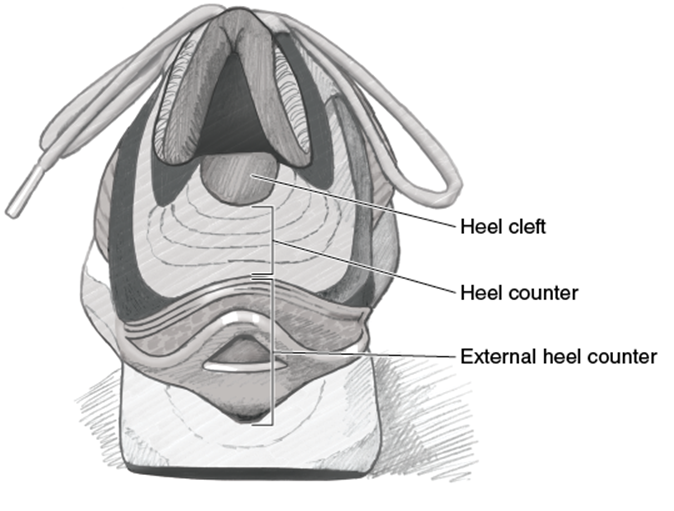

In conjunction with proper fit, a heel counter embedded in the upper material ensures a secure, mildly stable ride when running. Heel counters (figure 11.3) are hard plastic devices that stabilize the rear foot, helping the foot through the normal cycle of heel strike, midfoot stance (avoiding excess pronation), forefoot supination (the outward rolling of the forefoot), and toe-off from the smaller toes of the foot. Heel counters can be removed in shoes manufactured for underpronators, but the possibility of Achilles tendinitis is increased because of the increased movement of the calcaneus and the subsequent pulling on the Achilles tendon.

Figure 11.3 Heel counters and heel clefts.

Midsole

The midsole of a running shoe (figure 11.4) is made of EVA (ethylene vinyl acetate) or rubberized EVA used to cushion or stabilize the ride of the shoe during foot strike. Developed in the early 1970s as a cushioning material to rival polyurethane (which is denser and heavier), EVA has been combined with other proprietary cushioning materials such as air and gel as well as engineering designs like wave plates, footbridges, cantilevers, and truss systems to minimize impact shock generated during the foot strike and to guide the foot through its normal path.

Figure 11.4 Midsole.

The holy grail of midsole technology has been to find a material that provides a moderately soft ride and has the durability to withstand compression, which limits the life span of the shoe. A reasonable expectation for a running shoe’s life is 350 to 500 miles. The development of a midsole that could provide 750 miles of consistently comfortable running would be a boon both to runners and to the manufacturing company that patented the material.

The current crop of rubberized midsoles provide dramatically better cushioning than their “sheet” EVA predecessors from the 1970s, but there is an environmental cost associated with producing the material. Traditional EVA midsoles take approximately 1,000 years to entirely biodegrade. Some running shoe manufacturers are marketing eco-friendly “green” midsoles that are touted as environmentally sound because they degrade 50 times faster in a traditional landfill environment.

Most runners look at the outsoles of their shoes to determine whether the shoes need to be replaced. Unfortunately, when the outsole of a running shoe has worn away enough to show significant wear, the midsole has been long compromised in providing cushioning. Because midsoles provide cushioning, they also absorb and dampen the shock of impact. During a 30-minute run, each shoe lands on the ground approximately 2,700 times. That is multiplied by an impact force of three to four times a runner’s body weight, so it’s amazing that no more than a two-inch-thick wedge of EVA can withstand approximately 150 of these training runs before being replaced.

The midsole is also the part of the shoe that contains the various stability devices designed to prevent pronation. These devices are always placed on the medial side of the shoe, usually between the arch and the heel. The devices are located in this area to counter the effects of pronation, which is mainly controlled by the subtalar joint that is located in the area of the foot closest to this part of the shoe. Occasionally a shoe will be produced with forefoot posting (to prevent late-stage pronation of the forefoot), but this is a nontraditional method of design. Posting of the lateral side of the shoe is never done because increasing the rate and degree of pronation is problematic for pronators (leading to increased tibia discomfort) and needless for underpronators (a cushioned shoe allows for the foot to pronate as it needs to).

Outsole

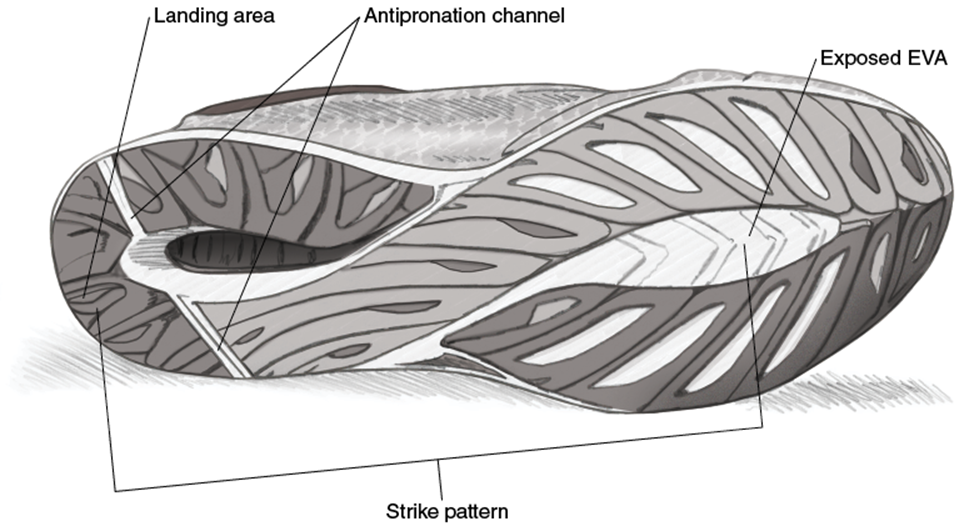

The outsole of a running shoe (figure 11.5) has evolved dramatically from a materials standpoint from the gum rubber of the 1908 Spalding marathon trainers. The outsole (the part of the shoe that actually touches the road) is made of carbon and blown rubber composites used jointly to make for a durable yet appropriately flexible ride. Most runners strike the lateral heel of the foot upon impact. Hence, manufacturers place the most durable carbon rubber in this area of the shoe to ensure longevity of the outsole. Despite the added durability of the carbon rubber, excessive wear will still appear in that area of the shoe for most runners. This is to be expected and does not indicate a proclivity toward overpronation or underpronation. It simply means the runner is a heel striker.

Figure 11.5 Outsole.

If the outsole is completely worn through in the forefoot of the shoe, the midsole cushioning was compromised long before, and the shoe is worthless as a shock-absorbing entity. Because the outsole of the shoe lasts much longer than the midsole cushioning, using outsole wear as a guide for when to replace your running shoes is erroneous. The best method of measuring the life of a shoe requires little work. Pay attention to the mileage on your shoes by keeping a log or quick estimation of miles per week multiplied by weeks of training, and after approximately 350 miles, replace your shoes when you begin to have aches or pains in your legs that you did not have for the first 350 miles of the shoe’s life. Normally, if a shoe model is not correct for a runner’s biomechanics, weight, flexibility, or foot shape (all factors that determine the best shoe), discomfort or injury will occur within the first 100 miles of running. Thus, the wrong shoe should rarely be confused with an old shoe.

Shoe manufacturers are constantly altering the strike path of a shoe’s outsole and the surface pattern of the rubber to improve comfort and durability. Although these aims of the manufacturers seem to be worthwhile, the role of aesthetics in shoe design cannot be ignored. At every phase of design and development, the aesthetics of the shoe, its attractiveness to the consumer, must be weighed against the practicality of building the shoe and the effectiveness of the shoe for running purposes. Often the aesthetics of the shoe take precedence, and a much-hyped shoe proves to be a performance dud—albeit a dud with an expensive advertising campaign.

Insoles and Orthotics

Runners want to wear comfortable running shoes that help prevent injuries; however, because running shoes are not custom-made, there will always be a bit of a compromise when it comes to fit. Because each runner’s foot is unique and not even symmetrical with the other foot, it becomes apparent that accommodations may be needed in order to enhance a running shoe’s fit and its function. To customize the fit and function of their shoes, runners turn to insoles and orthotics.

Each pair of running shoes comes with an insole. It is made of EVA or a material combined with EVA to add comfort (shock absorption) and to aid the fit of the shoe. It costs less than 50 cents to manufacture, and it is mostly useless. It is removable, and for a good reason. Most runners remove the inexpensive insole and replace it with a more cushioned or more stable insole that actually has some resemblance to the shape of the human foot. In the past decade, over-the-counter replacement insoles have become a serious revenue generator for running specialty stores. The proliferation of these stores has led to more retail outlets for the sales of insoles, and the insole manufacturers have responded by producing good-quality products for less than $30.

It seems a bit redundant to spend $90 on a pair of shoes and $30 on a pair of insoles when you could just buy a $120 pair of running shoes. The true value of the insole is that it customizes the shoe to the runner’s foot. Thus, the $90 shoe feels closer to a perfect fit than the $120 shoe because it more closely resembles a shoe made from a mold of the runner’s own foot. Not only does the insole aid fit, but current insoles also help correct for poor biomechanics. They can be posted to compensate for pronation factors or high-arched to help prevent plantar fasciitis. They do work well, but they are not for every runner. Many runners can do without insoles because they do not have major biomechanical problems that their training will exacerbate. For those runners who have run a lot of miles in their lives, are training at a high volume, or have chronic injuries, insoles are a viable option. For those runners who do not find relief with an over-the-counter insole, the next step is to visit an expert (certified pedorthist or podiatrist) to obtain custom-made orthotics.

An orthotic device is meant to correct an anatomical or biomechanical abnormality. In theory, an orthotic device realigns the foot strike, which, in turn, alleviates any imbalances or weaknesses through the kinetic chain of events initiated by running. Do orthotics work? Sometimes.

Upon visiting a podiatrist or certified pedorthist, a runner should expect the following procedure to occur before an orthotic device is produced. The specialist should take a thorough history of running injuries, shoes worn, and remedies attempted. Measurements of leg length and an evaluation of joint mobility should be completed. X-rays can be taken, but they are often not necessary.

After evaluating the feet, the specialist will proceed to make plaster molds of them. The doctor will place each foot in a “neutral” position and wrap plaster-soaked strips of gauze around each one. The most important step is placing the foot in the neutral position. This position is the key element in producing an orthotic that works well. Because the goal of an orthotic is to correct, the foot must be in the neutral position so a cast can be fabricated that shows any corrections to be made. The difference between the runner’s foot and the appropriate position of the runner’s foot when in neutral is the correction that needs to be made. When the cast is sent to an orthotics lab to produce the orthotic, a technician will evaluate the cast and take more measurements. From the “negative” cast, a “positive” model is created from plaster and is ground to the specifications provided by the doctor.

A hard orthotic is fabricated from thermoplastic and filled with cushioning material. It is posted medially no more than 4 degrees to help position the foot in neutral at midstance. It is covered by a thin layer of synthetic material. A soft orthotic, also referred to as an accommodative orthotic, is more of a custom-made arch support than a posted orthotic. Its goal is less medial stabilization for pronation and more arch support for a runner with high, rigid arches.

Normally, a running orthotic will be full length, replacing the insole of the shoe. It is not uncommon for a laboratory to offer a three-quarter-length orthotic. Because most rear-foot motion issues can be alleviated with a three-quarter-length orthotic, logic would dictate that the weight-saving inherent to a three-quarter-length orthotic would be welcome. Unfortunately, the lack of a continuous surface under the complete length of the foot leads runners to fabricate their own system of completing the orthotic. Purchase an orthotic with a full-length cover.

The litmus test of a well-constructed orthotic is twofold. Does it fit comfortably into a running shoe (although it may be a different, larger shoe than you were wearing), and does the orthotic device eliminate the running injuries it was created to combat without causing other injuries? The answer should be a resounding yes! If not, contact your doctor for a follow-up appointment to reevaluate the orthotic.

The pairing of an orthotic device and a running shoe is a combination of art and science. If a hard, corrective orthotic is worn, a neutral cushioned shoe that encompasses the orthotic well and provides a good fit may suffice in eliminating any overpronation injuries. If a stability shoe is still needed with a hard, corrective orthotic, take caution to avoid the possibility of overposting the foot. This marriage of a stability shoe and corrective orthotic is a possible recipe for iliotibial band syndrome, an injury usually associated with underpronators who stay on the lateral aspect of their foot through the foot strike, creating tightness in all the muscles and soft tissue laterally from the foot to the hip. At the first sign of pain on the lateral side of the knee or tightness in the hip area, reconsider the use of a stability shoe and corrective orthotic.

Underpronators who wear accommodative orthotics should continue to wear cushioned shoes. The only caveat, and this is true for overpronators with orthotics as well, is that an extra half size may be needed in order to fit the orthotic into a running shoe. The orthotic replaces the insole that comes with the shoe, but it is higher in volume and thus needs to be fit properly so that the biomechanics it is meant to promote during running can proceed seamlessly.

Barefoot Running

Barefoot running could have been included in chapter 9’s list of exercises to strengthen the foot because that is essentially what barefoot running does best (along with developing some proprioceptive awareness). But daily barefoot training is not really a substitute for running in shoes. Given that most runners log the majority of their miles on asphalt, concrete, treadmills, and gravel-strewn trails, running barefoot daily seems a bit painful at the least; however, running without shoes does have many practical applications when used as a supplement to running training, much like the strength-training exercises outlined in chapters 5 and 6 of this book. It should not replace traditional (with shoes) training. The argument has been made that many African runners have trained barefoot and have had success (native South African Zola Budd is a famous example), but the counterargument is that all the world records are held by shoe-wearing runners.

Proponents of barefoot running tout the muscular strength gained through barefoot running, which is an accurate assessment in the proper context. Advocates of barefoot running also tout the psychological release derived from running on sand and lush grass, which may also be because sand and lush grass are normally found in places more likely to be idyllic, although it is a tenuous connection to aiding running performance.

The best reason to do some barefoot running on lush grass or hard-packed sand (not more than twice a week and no more than 100 meters straight for a total of 400 meters per session to begin) is to train the muscles of your feet to work differently than they do when running shoes are worn. Barefoot running forces the feet to work, preventing atrophy in the muscles of the foot that function the same way during every run in running shoes with or without orthotics. The antiorthotic movement in running espouses mixing in barefoot running and running in neutral shoes for overpronators to force the foot to strengthen itself to prevent future injuries. Just as the exercises in this book have detailed how to strengthen your body to improve running performance, barefoot running can help strengthen your feet to withstand the countless training miles required of them. As with all strength training, if you feel pain while barefoot running, stop.

Summary

The ultimate goal of a well-designed and constructed running shoe and orthotic device is to promote injury-free and comfortable running. Extra cushioning to limit the impact forces of the foot strike, stability devices adding medial posting to limit pronation generated by the subtalar joint, and transitional EVA densities to ease the transition from heel strike to midstance are all designed to meet this goal. Appropriate footwear and orthotic devices (matched to a runner’s biomechanical needs), when combined with the strength-training program for the lower leg and foot presented in chapter 9, should eliminate all leg and foot injuries. One caveat is that the running shoe and orthotic must be appropriate to the foot that wears it, and the shoe and orthotic device must be replaced when its cushioning, stability, and accommodative properties are compromised. Normally, a running shoe can be expected to last at least 350 miles, an aftermarket insole should last through every other shoe purchase, and a custom orthotic should last at least two years (although the cover may need to be replaced).

Trained employees at running specialty stores can help runners match current running shoes with the appropriate foot types and match feet with nonprescription insoles that provide similar protection as orthotic devices, but are not custom-made by a podiatrist.

The effectiveness of any running shoe and orthotic device hinges not just on biomechanics but also on fit. A well-constructed shoe that is the right biomechanical choice for a runner may not function correctly if the shoe is ill-fitted to the foot. When purchasing a shoe, make sure the shoe is neither too long or too short, nor too wide or too narrow. Also, try the new shoes with the orthotic device to be worn in order to replicate the fit of the shoe-and-insert combination. Remember, if it doesn’t work in the store, it is not going to work on the road, trail, or track!